Intro

Build a custom Glock with our 80 Percent Glock Lower Guide, covering pistol frame assembly, machining, and compliance, for a personalized firearm with enhanced reliability and performance.

The world of firearms and gunsmithing has seen significant advancements in recent years, with the rise of DIY projects and customizations. One such trend that has gained popularity is the creation of 80% Glock lowers, which allow gun enthusiasts to build their own firearms from scratch. In this article, we will delve into the world of 80% Glock lowers, exploring their benefits, working mechanisms, and steps involved in building one.

Building a firearm from scratch can be a rewarding experience, allowing gun owners to customize their weapons to suit their specific needs and preferences. The 80% Glock lower is a popular choice among gun enthusiasts, as it provides a solid foundation for building a customized Glock pistol. With the right tools and knowledge, anyone can create their own 80% Glock lower, saving money and gaining a sense of accomplishment.

The process of building an 80% Glock lower requires careful planning and attention to detail. It involves machining and drilling the lower receiver, installing the necessary components, and ensuring that the firearm is safe and functional. While it may seem like a daunting task, building an 80% Glock lower can be a fun and rewarding experience, especially for those who enjoy DIY projects and gunsmithing.

Introduction to 80% Glock Lowers

An 80% Glock lower is a partially completed lower receiver that requires additional machining and drilling to become a fully functional firearm. It is called "80%" because it is 80% complete, with the remaining 20% requiring completion by the end-user. This allows gun enthusiasts to build their own firearms from scratch, while also complying with federal regulations.

The 80% Glock lower is a popular choice among gun enthusiasts, as it provides a solid foundation for building a customized Glock pistol. With the right tools and knowledge, anyone can create their own 80% Glock lower, saving money and gaining a sense of accomplishment. The process of building an 80% Glock lower requires careful planning and attention to detail, but the end result is well worth the effort.

Benefits of Building an 80% Glock Lower

There are several benefits to building an 80% Glock lower, including:

- Cost savings: Building an 80% Glock lower can be more cost-effective than purchasing a completed firearm.

- Customization: With an 80% Glock lower, gun enthusiasts can customize their firearms to suit their specific needs and preferences.

- Learning experience: Building an 80% Glock lower can be a fun and rewarding experience, especially for those who enjoy DIY projects and gunsmithing.

- Compliance with regulations: The 80% Glock lower allows gun enthusiasts to build their own firearms from scratch, while also complying with federal regulations.

Overall, building an 80% Glock lower is a great way for gun enthusiasts to create their own customized firearms, while also saving money and gaining a sense of accomplishment.

Working Mechanisms of an 80% Glock Lower

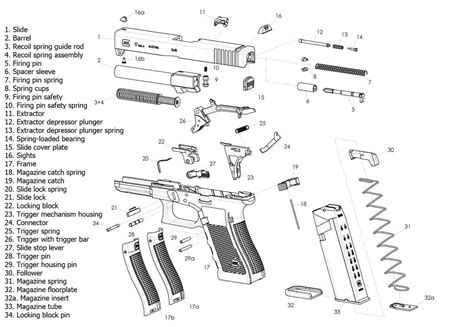

The working mechanisms of an 80% Glock lower are similar to those of a completed Glock pistol. The lower receiver is the foundation of the firearm, and it houses the magazine, trigger, and other essential components. The 80% Glock lower requires additional machining and drilling to become a fully functional firearm, but the end result is a reliable and accurate shooting platform.

Some of the key components of an 80% Glock lower include:

- Lower receiver: The lower receiver is the foundation of the firearm, and it houses the magazine, trigger, and other essential components.

- Trigger: The trigger is a critical component of the firearm, and it must be installed and adjusted properly to ensure safe and reliable operation.

- Magazine: The magazine is an essential component of the firearm, and it must be installed and adjusted properly to ensure reliable feeding and ejection.

Overall, the working mechanisms of an 80% Glock lower are similar to those of a completed Glock pistol, but they require additional machining and drilling to become fully functional.

Steps Involved in Building an 80% Glock Lower

Building an 80% Glock lower requires careful planning and attention to detail. The process involves machining and drilling the lower receiver, installing the necessary components, and ensuring that the firearm is safe and functional. Here are the steps involved in building an 80% Glock lower:

- Machining the lower receiver: The first step in building an 80% Glock lower is to machine the lower receiver. This involves using a milling machine or drill press to create the necessary holes and channels for the trigger, magazine, and other components.

- Drilling the trigger pin holes: The next step is to drill the trigger pin holes, which are used to secure the trigger in place.

- Installing the trigger: The trigger is a critical component of the firearm, and it must be installed and adjusted properly to ensure safe and reliable operation.

- Installing the magazine: The magazine is an essential component of the firearm, and it must be installed and adjusted properly to ensure reliable feeding and ejection.

- Assembling the firearm: The final step is to assemble the firearm, which involves installing the upper receiver, barrel, and other components.

Overall, building an 80% Glock lower requires careful planning and attention to detail, but the end result is a reliable and accurate shooting platform.

Tools and Materials Needed

To build an 80% Glock lower, you will need the following tools and materials:- Milling machine or drill press: A milling machine or drill press is necessary for machining the lower receiver and drilling the trigger pin holes.

- Trigger and magazine: The trigger and magazine are critical components of the firearm, and they must be installed and adjusted properly to ensure safe and reliable operation.

- Upper receiver and barrel: The upper receiver and barrel are essential components of the firearm, and they must be installed and adjusted properly to ensure reliable feeding and ejection.

- Safety glasses and ear protection: Safety glasses and ear protection are necessary to protect yourself from injury while working with power tools and firearms.

Overall, building an 80% Glock lower requires careful planning and attention to detail, but the end result is a reliable and accurate shooting platform.

80 Percent Glock Lower Image Gallery

What is an 80% Glock lower?

+An 80% Glock lower is a partially completed lower receiver that requires additional machining and drilling to become a fully functional firearm.

What are the benefits of building an 80% Glock lower?

+The benefits of building an 80% Glock lower include cost savings, customization, learning experience, and compliance with regulations.

What tools and materials are needed to build an 80% Glock lower?

+The tools and materials needed to build an 80% Glock lower include a milling machine or drill press, trigger and magazine, upper receiver and barrel, and safety glasses and ear protection.

In conclusion, building an 80% Glock lower is a fun and rewarding experience that allows gun enthusiasts to create their own customized firearms. With the right tools and knowledge, anyone can build an 80% Glock lower, saving money and gaining a sense of accomplishment. Whether you're a seasoned gunsmith or a DIY enthusiast, building an 80% Glock lower is a great way to create a reliable and accurate shooting platform. So why not give it a try? Share your experiences and tips with others, and don't hesitate to ask for help if you need it. Happy building!