Intro

Discover the 5 Cadillac factories, exploring manufacturing processes, production lines, and assembly plants, highlighting American automotive innovation, luxury vehicle design, and engineering excellence.

The Cadillac brand has been an iconic symbol of American luxury and innovation for over a century. With a rich history that spans from its founding in 1902 to the present day, Cadillac has established itself as a leader in the automotive industry. One of the key factors that have contributed to the brand's success is its manufacturing capabilities. In this article, we will delve into the world of Cadillac factories, exploring their history, current operations, and the role they play in producing some of the most luxurious and technologically advanced vehicles on the market.

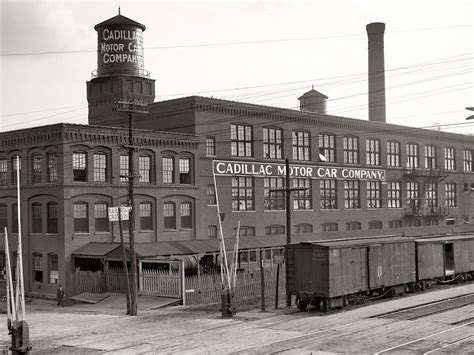

The early days of Cadillac were marked by a commitment to quality and innovation. The company's founder, Henry Leland, was a pioneer in the automotive industry, and his vision for Cadillac was to create a brand that would be synonymous with excellence. This vision was realized through the establishment of Cadillac's first factory in Detroit, Michigan. The factory, which was opened in 1902, was equipped with state-of-the-art machinery and staffed by skilled craftsmen who were dedicated to producing the highest quality vehicles.

As the years passed, Cadillac continued to grow and expand its operations. The company opened new factories in various locations, including Cleveland, Ohio, and Detroit, Michigan. These factories were designed to meet the increasing demand for Cadillac vehicles, which were becoming increasingly popular among American consumers. The factories were also equipped with the latest technology, allowing Cadillac to stay ahead of the curve in terms of innovation and quality.

Today, Cadillac operates a number of factories around the world, including five main factories in the United States and China. These factories are responsible for producing a wide range of Cadillac models, from the compact ATS sedan to the full-size Escalade SUV. In this article, we will take a closer look at each of these factories, exploring their history, current operations, and the role they play in the production of Cadillac vehicles.

Cadillac Factory 1: Detroit-Hamtramck Assembly

The Detroit-Hamtramck Assembly factory is one of the oldest and most historic Cadillac factories. Located in Detroit, Michigan, the factory has been in operation since 1980 and has produced a wide range of Cadillac models over the years. The factory is currently responsible for producing the Cadillac CT6 sedan, as well as the Chevrolet Volt and Chevrolet Impala. With a workforce of over 1,500 employees, the Detroit-Hamtramck Assembly factory is one of the largest and most productive Cadillac factories in the world.

Cadillac Factory 2: Lansing Grand River Assembly

The Lansing Grand River Assembly factory is located in Lansing, Michigan, and has been in operation since 2001. The factory is responsible for producing the Cadillac ATS and CTS sedans, as well as the Chevrolet Camaro. With a workforce of over 1,200 employees, the Lansing Grand River Assembly factory is one of the most technologically advanced Cadillac factories in the world. The factory is equipped with state-of-the-art machinery and is designed to produce high-quality vehicles with precision and efficiency.

Cadillac Factory 3: Spring Hill Manufacturing

The Spring Hill Manufacturing factory is located in Spring Hill, Tennessee, and has been in operation since 1990. The factory is responsible for producing the Cadillac XT5 and XT4 crossovers, as well as the GMC Acadia and Holden Acadia. With a workforce of over 2,000 employees, the Spring Hill Manufacturing factory is one of the largest and most productive Cadillac factories in the world. The factory is equipped with state-of-the-art machinery and is designed to produce high-quality vehicles with precision and efficiency.

Cadillac Factory 4: Arlington Assembly

The Arlington Assembly factory is located in Arlington, Texas, and has been in operation since 1954. The factory is responsible for producing the Cadillac Escalade and Chevrolet Tahoe and Suburban SUVs. With a workforce of over 3,500 employees, the Arlington Assembly factory is one of the largest and most productive Cadillac factories in the world. The factory is equipped with state-of-the-art machinery and is designed to produce high-quality vehicles with precision and efficiency.

Cadillac Factory 5: Jinqiao Cadillac Plant

The Jinqiao Cadillac Plant is located in Shanghai, China, and has been in operation since 2013. The factory is responsible for producing the Cadillac XT5 and CT6 sedans for the Chinese market. With a workforce of over 1,000 employees, the Jinqiao Cadillac Plant is one of the most technologically advanced Cadillac factories in the world. The factory is equipped with state-of-the-art machinery and is designed to produce high-quality vehicles with precision and efficiency.

Benefits of Cadillac Factories

The Cadillac factories play a crucial role in the production of high-quality vehicles. Some of the benefits of these factories include: * High-quality vehicles: The Cadillac factories are equipped with state-of-the-art machinery and staffed by skilled craftsmen who are dedicated to producing the highest quality vehicles. * Precision and efficiency: The factories are designed to produce vehicles with precision and efficiency, ensuring that every vehicle meets the highest standards of quality and performance. * Job creation: The Cadillac factories provide employment opportunities for thousands of people, contributing to the local economy and community. * Innovation: The factories are equipped with the latest technology, allowing Cadillac to stay ahead of the curve in terms of innovation and quality.Working Mechanisms of Cadillac Factories

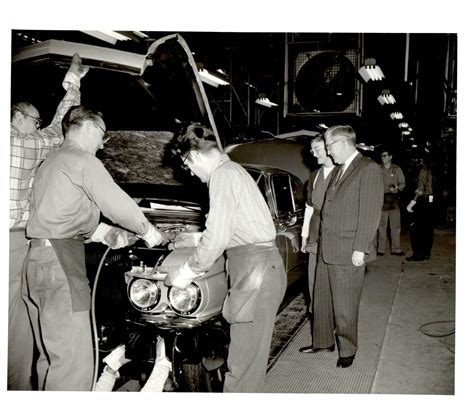

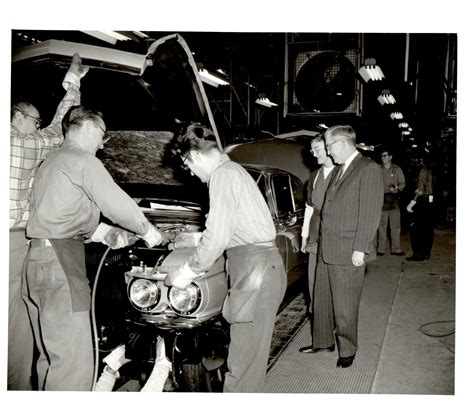

The Cadillac factories operate using a combination of traditional manufacturing techniques and cutting-edge technology. Some of the key working mechanisms of these factories include: * Assembly lines: The factories use assembly lines to produce vehicles, with each station on the line responsible for a specific task, such as welding or painting. * Robotics: The factories use robotics to automate many tasks, such as welding and assembly, increasing efficiency and precision. * Quality control: The factories have strict quality control measures in place to ensure that every vehicle meets the highest standards of quality and performance. * Supply chain management: The factories work closely with suppliers to ensure that all parts and materials are delivered on time and to the required specification.Cadillac Factory Image Gallery

What is the history of Cadillac factories?

+The history of Cadillac factories dates back to 1902, when the company's founder, Henry Leland, opened the first Cadillac factory in Detroit, Michigan. Since then, the company has expanded its operations to include five main factories in the United States and China.

What models are produced at each Cadillac factory?

+The models produced at each Cadillac factory vary. The Detroit-Hamtramck Assembly factory produces the Cadillac CT6 sedan, while the Lansing Grand River Assembly factory produces the Cadillac ATS and CTS sedans. The Spring Hill Manufacturing factory produces the Cadillac XT5 and XT4 crossovers, and the Arlington Assembly factory produces the Cadillac Escalade and Chevrolet Tahoe and Suburban SUVs. The Jinqiao Cadillac Plant produces the Cadillac XT5 and CT6 sedans for the Chinese market.

What is the role of robotics in Cadillac factories?

+Robotics play a crucial role in Cadillac factories, automating many tasks such as welding and assembly. This increases efficiency and precision, allowing the factories to produce high-quality vehicles with minimal defects.

How many employees work at each Cadillac factory?

+The number of employees working at each Cadillac factory varies. The Detroit-Hamtramck Assembly factory has a workforce of over 1,500 employees, while the Lansing Grand River Assembly factory has a workforce of over 1,200 employees. The Spring Hill Manufacturing factory has a workforce of over 2,000 employees, and the Arlington Assembly factory has a workforce of over 3,500 employees. The Jinqiao Cadillac Plant has a workforce of over 1,000 employees.

What is the future of Cadillac factories?

+The future of Cadillac factories is exciting, with plans to expand and modernize existing facilities. The company is also investing in new technologies, such as electric and autonomous vehicles, to stay ahead of the curve in the automotive industry.

In conclusion, the Cadillac factories play a vital role in the production of high-quality vehicles. With a rich history dating back to 1902, the company has established itself as a leader in the automotive industry. The five main factories in the United States and China are responsible for producing a wide range of Cadillac models, from the compact ATS sedan to the full-size Escalade SUV. We invite you to share your thoughts on the Cadillac factories and their role in the automotive industry. Please comment below and let us know what you think. You can also share this article with your friends and family to spread the word about the exciting world of Cadillac factories. Thank you for reading!