Intro

Improve welding skills with 5 expert tips, covering MIG, TIG, and arc welding techniques, safety precautions, and metal preparation for strong, precise joints and professional results.

Welding is a complex process that requires a great deal of skill and practice to master. Whether you're a seasoned professional or just starting out, there are always ways to improve your technique and produce high-quality welds. In this article, we'll explore five welding tips that can help you take your skills to the next level. From safety precautions to technique adjustments, these tips will help you become a more confident and competent welder.

Welding is a vital skill that is used in a wide range of industries, from construction and manufacturing to automotive and aerospace. It requires a great deal of precision and attention to detail, as well as a strong understanding of the materials and equipment being used. By following these five welding tips, you can improve your skills and produce high-quality welds that meet the needs of your project. Whether you're working on a small repair job or a large-scale construction project, these tips will help you achieve professional-grade results.

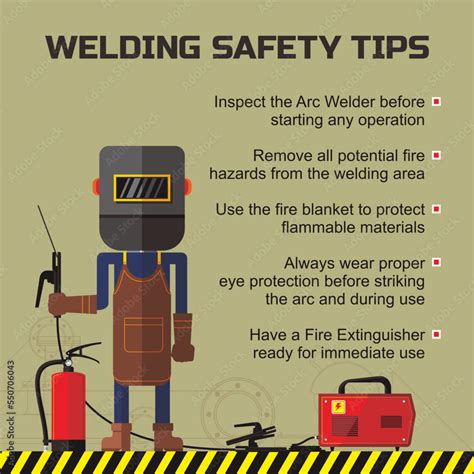

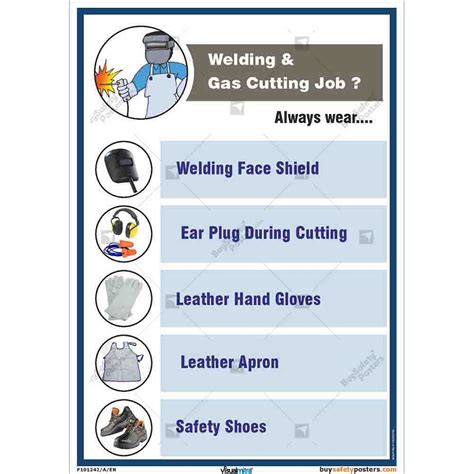

One of the most important things to keep in mind when welding is safety. Welding can be a hazardous activity, with risks of burns, electrical shock, and eye damage. To minimize these risks, it's essential to take the necessary safety precautions. This includes wearing protective gear such as gloves, safety glasses, and a welding helmet, as well as ensuring that your workspace is well-ventilated and free from flammable materials. By taking these precautions, you can help prevent accidents and ensure a safe and healthy working environment.

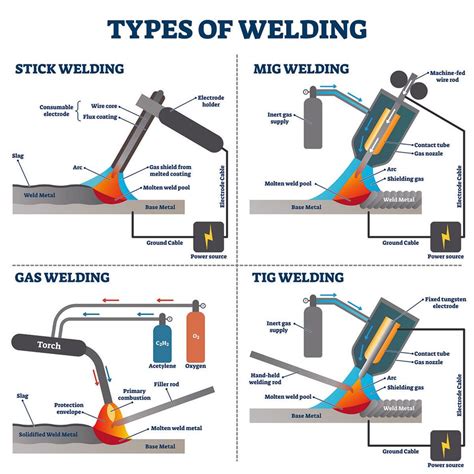

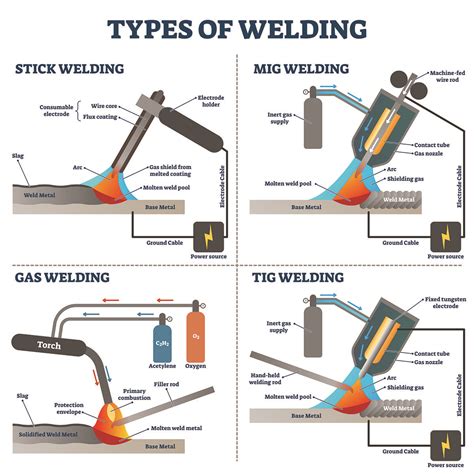

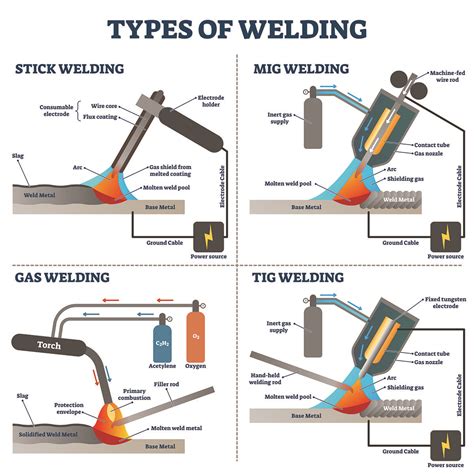

Understanding Welding Techniques

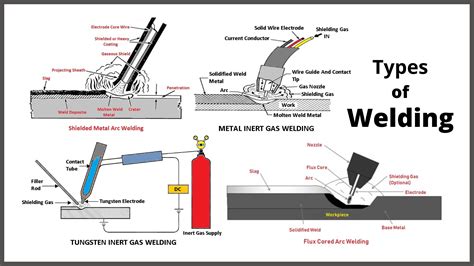

There are several different welding techniques, each with its own unique characteristics and applications. Some of the most common techniques include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and gas tungsten arc welding (GTAW). Each of these techniques requires a different set of skills and equipment, and it's essential to understand the basics of each technique in order to produce high-quality welds. By understanding the different welding techniques and how they are used, you can choose the best technique for your project and achieve professional-grade results.

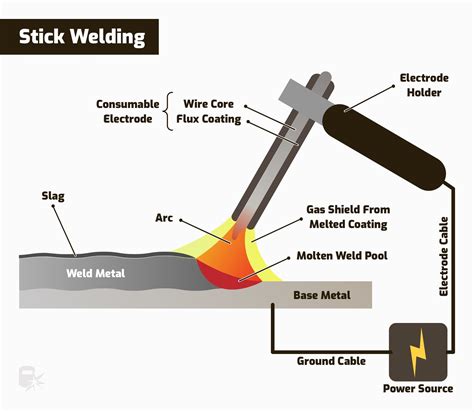

Shielded Metal Arc Welding (SMAW)

Shielded metal arc welding, also known as "stick" welding, is a common technique that uses a consumable electrode covered in flux to lay the weld. This technique is often used for repair work and construction projects, as it is relatively simple and inexpensive. However, it can be more difficult to produce high-quality welds with SMAW, as the flux can create slag and porosity in the weld. To overcome these challenges, it's essential to use the correct electrode and welding technique, as well as to clean and prepare the metal surface properly.Gas Metal Arc Welding (GMAW)

Gas metal arc welding, also known as "MIG" welding, is a technique that uses a continuous wire electrode and an inert gas to shield the weld. This technique is often used for production work and fabrication projects, as it is relatively fast and easy to use. GMAW produces high-quality welds with minimal slag and porosity, making it a popular choice for many industries. However, it can be more expensive than SMAW, and requires a greater degree of skill and practice to master.

Gas Tungsten Arc Welding (GTAW)

Gas tungsten arc welding, also known as "TIG" welding, is a technique that uses a non-consumable tungsten electrode and an inert gas to shield the weld. This technique is often used for precision work and fabrication projects, as it produces high-quality welds with minimal slag and porosity. GTAW is a more complex technique than SMAW or GMAW, and requires a greater degree of skill and practice to master. However, it is often used for high-precision applications, such as aerospace and automotive manufacturing.Welding Safety Precautions

Welding safety precautions are essential to preventing accidents and ensuring a safe and healthy working environment. Some of the most important safety precautions include wearing protective gear such as gloves, safety glasses, and a welding helmet, as well as ensuring that your workspace is well-ventilated and free from flammable materials. It's also essential to follow proper welding techniques and to use the correct equipment for the job. By taking these precautions, you can help prevent accidents and ensure a safe and healthy working environment.

Proper Ventilation

Proper ventilation is essential to preventing the buildup of fumes and particles in the air. This can be achieved by using a ventilation system or by working in a well-ventilated area. It's also essential to avoid welding in confined spaces, as this can increase the risk of accidents and health problems. By ensuring proper ventilation, you can help prevent the buildup of fumes and particles in the air and create a safe and healthy working environment.Welding Equipment Maintenance

Welding equipment maintenance is essential to ensuring that your equipment is in good working order and that you can produce high-quality welds. This includes regularly cleaning and inspecting your equipment, as well as replacing worn or damaged parts. It's also essential to follow the manufacturer's instructions for maintenance and repair, as this can help prevent accidents and ensure that your equipment is working properly. By maintaining your equipment properly, you can help ensure that you can produce high-quality welds and achieve professional-grade results.

Regular Cleaning

Regular cleaning is essential to preventing the buildup of dirt and debris on your equipment. This can be achieved by using a soft brush or cloth to wipe down your equipment, as well as by using a cleaning solution to remove any tough stains or grime. It's also essential to clean your equipment after each use, as this can help prevent the buildup of dirt and debris and ensure that your equipment is in good working order. By regularly cleaning your equipment, you can help ensure that you can produce high-quality welds and achieve professional-grade results.Welding Technique Adjustments

Welding technique adjustments are essential to producing high-quality welds. This includes adjusting the welding speed, voltage, and current, as well as using the correct welding technique for the job. It's also essential to practice regularly, as this can help you develop the skills and muscle memory needed to produce high-quality welds. By making adjustments to your welding technique, you can help ensure that you can produce high-quality welds and achieve professional-grade results.

Practicing Regularly

Practicing regularly is essential to developing the skills and muscle memory needed to produce high-quality welds. This can be achieved by setting aside time each week to practice welding, as well as by working on a variety of projects to develop your skills. It's also essential to seek feedback from others, as this can help you identify areas for improvement and develop your skills more quickly. By practicing regularly, you can help ensure that you can produce high-quality welds and achieve professional-grade results.Common Welding Mistakes

Common welding mistakes can be costly and time-consuming to fix. Some of the most common mistakes include using the wrong welding technique, not cleaning the metal surface properly, and not using the correct equipment for the job. It's also essential to avoid distractions while welding, as this can increase the risk of accidents and mistakes. By being aware of these common mistakes, you can help ensure that you can produce high-quality welds and achieve professional-grade results.

Avoiding Distractions

Avoiding distractions is essential to producing high-quality welds. This can be achieved by creating a quiet and comfortable working environment, as well as by minimizing interruptions and distractions. It's also essential to stay focused and alert while welding, as this can help you avoid mistakes and accidents. By avoiding distractions, you can help ensure that you can produce high-quality welds and achieve professional-grade results.Welding Image Gallery

What is the most common welding technique?

+The most common welding technique is shielded metal arc welding (SMAW), also known as "stick" welding.

What is the importance of welding safety precautions?

+Welding safety precautions are essential to preventing accidents and ensuring a safe and healthy working environment.

What is the difference between GMAW and GTAW welding techniques?

+GMAW (gas metal arc welding) and GTAW (gas tungsten arc welding) are two different welding techniques that use different equipment and techniques to produce welds.

How often should I practice welding to improve my skills?

+It's recommended to practice welding regularly, at least once a week, to develop the skills and muscle memory needed to produce high-quality welds.

What are some common welding mistakes to avoid?

+Some common welding mistakes to avoid include using the wrong welding technique, not cleaning the metal surface properly, and not using the correct equipment for the job.

In conclusion, welding is a complex process that requires a great deal of skill and practice to master. By following these five welding tips, you can improve your skills and produce high-quality welds that meet the needs of your project. Remember to always follow safety precautions, use the correct equipment and technique, and practice regularly to develop your skills. With time and practice, you can become a skilled welder and achieve professional-grade results. We hope you found this article informative and helpful in your welding journey. If you have any questions or comments, please don't hesitate to share them with us.